components and part

-

Hot

Five axis processing of SLR Lens

Advanced machining equipment, reasonable craftsmanship and strict quality control strictly control every production procedure. Do once and do it right, It is the biggest delivery guarantee for Mission Gauge There are 30 sets of 3 axis CNC machines and 4 sets of Gantry machining centres with max. machining scope 6 meters, and there are 6 sets 5-axis CNC from Germany DMU and Italy Breton , with auto-programming software, meeting the high-precision processing requirements of various large-sized special-curved workpieces. At the same time we Introduced SAP and Eman management systems to control the production progress in real time. High-efficiency, smart manufacturing, all in Mission. technology- leading and quality- brand ---- Fully in Mission.

Email Details -

Hot

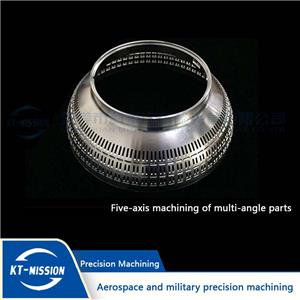

Five axis machining of multi angle parts

Advanced machining equipment, reasonable craftsmanship and strict quality control strictly control every production procedure. Do once and do it right, It is the biggest delivery guarantee for Mission Gauge There are 30 sets of 3 axis CNC machines and 4 sets of Gantry machining centres with max. machining scope 6 meters, and there are 6 sets 5-axis CNC from Germany DMU and Italy Breton , with auto-programming software, meeting the high-precision processing requirements of various large-sized special-curved workpieces. At the same time we Introduced SAP and Eman management systems to control the production progress in real time. High-efficiency, smart manufacturing, all in Mission. technology- leading and quality- brand ---- Fully in Mission.

Email Details -

Hot

Aerospace and military precision machining class, all precision machining

Five-axis machining turbine Advanced machining equipment, reasonable craftsmanship and strict quality control strictly control every production procedure. Do once and do it right, It is the biggest delivery guarantee for Mission Gauge There are 30 sets of 3 axis CNC machines and 4 sets of Gantry machining centres with max. machining scope 6 meters, and there are 6 sets 5-axis CNC from Germany DMU and Italy Breton , with auto-programming software, meeting the high-precision processing requirements of various large-sized special-curved workpieces. At the same time we Introduced SAP and Eman management systems to control the production progress in real time. High-efficiency, smart manufacturing, all in Mission. technology- leading and quality- brand ---- Fully in Mission.

Email Details -

Hot

Car spare parts

Mission Gauge & Fixture has won the title of "Guangdong Province High-tech Enterprise and Product" Has ISO9001 certificates and more than 50 Chinese national patents We pay attention to the training of technicians, technology research and development, realizing automatic design, automatic drawing and our efficiency increases by more than 20%. At same time, Mission Gauge & Fixture are continuing investment in R&D automation To keep learning the current & future needs of OEM manufacturers Deepen the understanding of current technology meet the growing expectations of customers through excellent engineering technology and overall solutions

Email Details