assembly

-

Hot

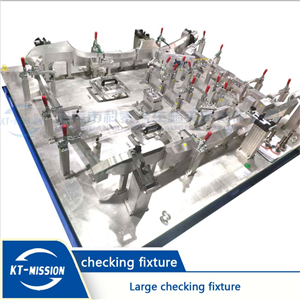

Roof checking fixture

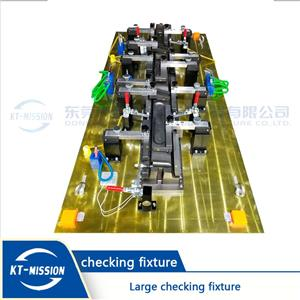

1. Provide a series of roof gauges, checking fixture / assembly checking fixture / holding fixture, a complete service can save you lots of time, energy and cost.. 2. We can fulfill your gauges demands from 1 pc small - big size & big package, building & inspection in house ability, max size 5 meters.

Email Details -

Hot

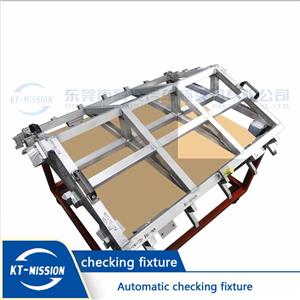

Automatic checking fixture

Automatic checking fixture.A fixture company that has reached European and American quality standards.Your Reliable Supplier for Checking Fixtures and Welding Jigs.Cubing(Car Cubing UCF PCF) Checking Fixtures for Automotives Welding Automation Fixtures for Automotives Non-standard Precision fixtures

Email Details -

Hot

Sunroof assembly checking fixture

Sunroof assembly checking fixture It is used to locate assembly parts. It is used to quickly and intuitively check holes, mating surfaces, contours and other main features with a hand gauge to verify whether the product is qualified.

Email Details -

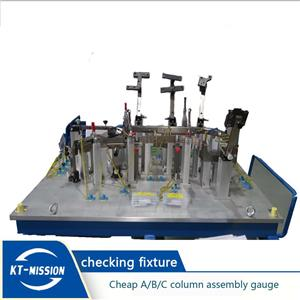

Cheap A/B/C column assembly gauge for stamping part

Start checking fixture business in 2008, registered on 2013, specialized in checking fixtures, welding jigs and welding work stations for automotive parts. Mission Has become a well-known supplier at home and abroad.8600㎡ plant area, 180 employees in total for check fixtures . Registered capital of 4 million USD, Annual turnover 17 million USD. With 1000㎡ separate plant and 50 staffs for welding jig.ISO9001:2015 certificated. State-level high-tech enterprise. 30 national patents6 sets of 5-axis CNC machines imported from Germany/Italy, 36 sets of 3-axis CNC machines from Taiwan 8 sets of CMM checking mechines. Industry-leading human and equipment resources, to ensure highy accuracy requirement, and to be the leader in the industry.Main Customer:Magna、Valeo、Yanfeng、Martinrea、Metalsa、Kirchhoff 、Johnson Control 、Toyota、Honda、FAW Volkswagen、FAW CAR、Dongfeng Motor、Nissan、Geely、Ford、GAGC、HAIMA、Xiaopeng、MITSUBISHI、Hong Qi、BJC、South-East、BYD etc;Mission policy”Customer First, Delivery on Time, Make Customer Satisfied”, vision”To build First-class Enterprises and Achieve Positive Life”

Email Details -

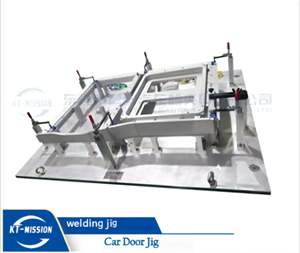

car door assembly gauge for stamping parts

car door assembly gauge for stamping parts

Email Details -

high quality car door assembly gauge

car door assembly gauge It is used to locate assembly parts. It is used to quickly and intuitively check holes, mating surfaces, contours and other main features with a hand gauge to verify whether the product is qualified.

Email Details -

Automotive Parts Car Threshold Checking Fixture

automation Automatic tool setting Automatic tool change Automatic programming: unified template, automatic program list Automation transformation: robots instead of labor

Email Details -

car door assembly gauge for plastic assembly stamping part checking fixture

Equipment capacity: 1.Work in two shift to ensure max capacity 2.Monthly accuracy check to ensure quality 3.The fastest delivery:25days Operation Process Standardization: 1.Uniform processing,measuring,tool usin mapping, bracket programming,base 2.Programming and five-axis programming standards Process Standardization 1.Process design review -Receive the following figure information-Making timing plan-allocating task -Main programming- Program audit-Delivery site manager - Delivery Five-axis programming standards: 1.Clamping-Trial knife -Medium light-Semi polishing-Polishing-Clearance angle - rework-holes

Email Details -

Right back door gauge

Right back door gauge car door assembly gauge It is used to locate assembly parts. It is used to quickly and intuitively check holes, mating surfaces, contours and other main features with a hand gauge to verify whether the product is qualified.

Email Details